Though many millions of people enjoy rooibos tea the world over today, not many would be able to answer the question of ‘How is rooibos tea processed?’. To provide an answer to that question, this article provides insights into modern rooibos tea processing.

The short answer is that rooibos tea processing involves harvesting, cutting, sorting and sweating in order to produce the rich red-amber coloured ‘tea’ that’s known to rooibos lovers the world over. But there is a lot more to it than it sounds – so come with us as we delve into the steps and details involved in rooibos tea processing, from the fields of the Cederberg to your cup.

The methods of collection and rooibos tea processing have seen significant changes since the turn of the 19th century. Whereas many of today’s large rooibos producers make use of state-of-the-art technology to harvest, cut, sweat, dry, grade and pack rooibos tea, early rooibos pickers used more rudimentary methods to harvest and process the raw tea.

Elements of the mechanisation developed in Britain for making black tea were later adapted for rooibos production, such as cutting the tea evenly with chaff-cutters, rather than with hand-axes. As production grew over time, rooibos tea processing became more controlled and producers learned how to improve the quality of rooibos tea.

Though the basics of rooibos tea processing follow much the same steps, the development of technology has meant that today’s rooibos industry has access to a far wider range of specialist equipment for each of these stages.

There is some art involved in making good quality rooibos. The various factors include:

- having high-quality rooibos plants, and growing these in a high-quality production region

- harvesting at the right time in the rooibos plant’s life cycle

- ensuring that there are no other plants* or other substances are found in the harvested rooibos

- controlling the feeding of material into the cutting machines

- the length of cut

- the sharpness of the blades and proper adjustment of the machines

- the crushing and compaction of the oxidation heaps (also called “sweat heaps” or “fermentation heaps” although technically this is not a fermenting process)

- the controlled adding of water

- the temperature obtained in the heaps

- alternatively aerating and compacting the heaps

- the spreading out of the finished tea to dry in the sun

All of these are critical steps in rooibos tea processing, and as with the processing of any organic product, some delicate fine-tuning of these steps and others all have a role to play in determining whether the rooibos ends up as a top-quality cup of rooibos tea.

*we cover potential dangers of contaminants in our ‘PA’s in Rooibos’ article.

Modern Processing and Standards

Modern rooibos tea processing quality controls come from the major players in the industry, and the SA Rooibos Council and South African Department of Agriculture. These standards cover food handling, phytosanitary controls and export quality. Included in these standards are stipulations for the testing of rooibos products for organisms such as Salmonella, E.coli and other microbacteria.

Any rooibos sold locally in South Africa or internationally goes through residue herbicide and pesticide testing to meet relevant standards – for conventional rooibos there are minimum thresholds, and for rooibos to be certified as organic, the end product may not have any residues. Analysis to provide reports on residues, herbicides, pesticides and microbes is performed by a wide range of accredited laboratories both in South Africa and across the world – and tea clients may on occasion wish to perform their own tests, above and beyond those performed on representative samples sent prior to the shipping of bulk rooibos.

On occasion, some discerning importers will also test for one or more of the following items: PAs and TAs, yeasts & moulds, heavy metals, Glyphosate and other specialist tests. Of particular importance for the EU market, Pyrrolizidine and Tropane alkaloids (known as PAs and TAs) are of concern, and testing for these is thus included as and when tea traders and brands in this region place orders from producers. Generally speaking, the parameters and spectrum of residue testing can also include heavy metals.

For all rooibos exports, these have to pass testing that is managed by the Perishable Products Export Control Board (PPECB), which requires farms to be SAGAP certified, and if they have a drying facility, this would similarly need to be certified. In some cases, standards that go beyond the specified list governed by the PPECB – and in these cases producers and tea traders and buyers come to agreement on other standards aligned to the interests and regulations of the specific region within which the rooibos would be marketed, distributed or sold.

Generally, at the secondary rooibos tea processing level, all of these factories and facilities also require certifications in line with export regulation and client requirements. Certifications for these include FSSC22000 as well as ISO ratings specific to the nature of their operations. In addition to these standards and certifications, the full chain of custody of organic rooibos products involves auditing and certification from international organic and ethical bodies such as Rainforest Alliance, UEBT and Fair Trade.

There is no written handbook for how to make rooibos tea, and for good commercial reasons details are not published. However, consequently there are a wide range of similar approaches taken in the industry which largely result in similar product output commensurate with varying rooibos quality grades at the relevant quality levels.

The Stages of Rooibos Processing

From start to finish, rooibos is processed in the following steps:

1) Primary Processing

This is the all-important stage when the rooibos crop is harvested and processed into rooibos tea. Located as it is in the Cederberg region of South Africa (and it is only in this region that rooibos is grown anywhere in the world), harvest takes place in the Southern Hemisphere summer between December and March. The timing of harvest is typically late December or early January, depending on seasonal rainfall and when the rooibos is ripe, and continues up until as late as early March. Processing follows on the heels of harvest once the rooibos has been hand-cut with sickles and brought in from the fields.

Once primary processing is complete, you could in fact make a cup of rooibos tea from the material coming off the tea court and enjoy a flavourful cup. This is the alchemical phase, during which the magic of organic chemistry and the mastery of the rooibos maker come to bear.

What ultimately determines quality is where rooibos is produced and how primary processing is handled. Secondary processing (which we describe below) and the remaining processes essentially take an already finished product and prepare and package it in order to be ‘market presentable’ and ready for distribution and sale once delivered to the market within which it will be marketed.

Once harvested, rooibos is brought in from the fields, it is carefully sorted on sorting tables, and then fed through tea-cutting machines (known as ‘carving’ machines, as seen below in the primary processing facility at our estate).

The carving machines maintain a uniform cut length to ensure a neat and consistent appearance of the final product. The rate at which rooibos is fed into the cutting machines determines the rooibos cut lengths from extremely fine espresso cuts to Short/Teabag cuts and Long/Coarse loose-leaf cuts.

At most farms or processing facilities, the carving machines feed the tea directly into wagons, hoppers or bins. Over the course of the day, the wagons empty the cut green rooibos onto the tea court in long rows (or ‘sweethope’ / ‘sweat heaps’). It’s here that the magical process of green cut rooibos transforming into into its characteristic red colour takes place, under the dry heat of the Cederberg summer sun.

Towards the end of the day, the sweat heaps are watered and rotavated (shown below) to introduce moisture and oxygen critical to ‘fermentation’. Strictly speaking, rooibos does not undergo fermentation: the process is more correctly named enzymatic oxidation, as the transformation of rooibos from green to amber brown/red involves enzymes that cause the polyphenols in the leaf matter to mature, producing not only a change in colour, but also a marked increase in aroma and taste.

The rooibos is then left overnight to ‘sweat’ further in the heat of Cederberg summer evenings. Once the rooibos has been through the carving machines and left to sweat on the tea court overnight, the next morning the green rooibos has transformed into its characteristic red/amber colour, with the wonderful flavour and sweet distinctive aroma that top-quality rooibos is known for.

The rooibos is then spread out across our tea court to dry 100% naturally in the hot African sun.

The cutting, fermenting & drying processes are completed in less than 24 hours, and the freshly made rooibos tea is “picked/sucked up” by a special machine (called an “Opteller” in Afrikaans) and fed into bulk bags. The bags are then stored for many years, or until required for onward delivery to traders or tea brands.

2) Secondary (Final) Processing and Packing

This phase consists of grading, sieving, blending & sterilisation, and finally packaging and packing. Each stage of this sequence is carefully monitored in order to ensure that the texture and density of the rooibos is maintained as per the final requirement. For example, Short/Fine Cut is used in the processing for “teabag cut”, and Long / Coarse Cut is principally used for ‘loose leaf’ tea, often blended by clients with fruits, herbs or flowers. Typically, sieving is done first, and thereafter sterilisation involves heat and/or steam treatment in which microbes, yeasts and moulds are eliminated or reduced to levels acceptable to food safety standards and client requirements.

The period of time and the way in which rooibos undergoes heat and steam treatment may vary, depending on client microbial specifications. Broadly speaking, rooibos needs to be heated for a minimum temperature and period to eradicate any possible organisms which may naturally be found in the growing environment, and which could be detrimental to consumer health, or the purity of the product. In performing this phase of secondary processing, qualifying facilities are required to have FSSC22000 and ISO 9001 certifications in order to be compliant with food safety standards.

At stages of processing, tests are performed by the secondary processor’s Quality Assurance team to check for contaminants (such as metal or plastic particles that may enter the raw material as a result of primary processing, or their own machinery and handling). This is in addition to swabs taken from machine parts and containers used in the processing and storage phases, which are routinely performed in order to verify that all components are safe, in line with auditing and safety certification requirements.

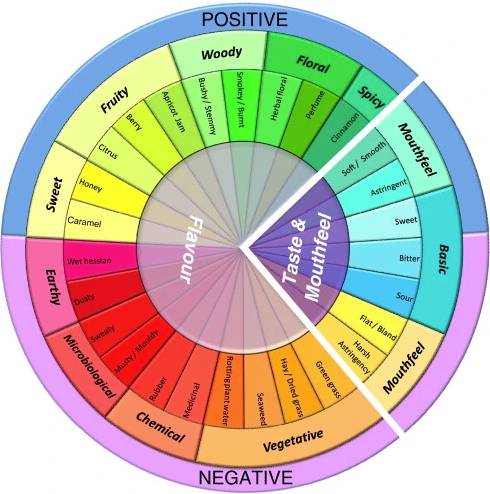

Beyond the testing mentioned above, secondary processors will also perform organoleptic tests to determine whether batches meet the taste, colour and aroma profiles expected. In performing organoleptic tests – and other than their own finely-tuned taste and smell – secondary processors make use of the Rooibos Colour Wheel, released in 2017, to guide them in verifying whether the processed rooibos meets the standards required.

3) Final Quality Testing

During this phase, following sterilisation and packing, pre-shipment samples are sent to accredited sent to accredited laboratories. Laboratory reports are reviewed prior to issuing of Certificates of Analysis and form part of the shipping documentation required for export.

It’s at these laboratories that analyses are performed to determine the levels of microbials, pesticides, residues and other pre-specified items. In order for the processed rooibos tea to be certified as safe for consumption in local or international markets, these tests need to be passed within given limits.

Green Rooibos Processing And Rooibos Extract

There are a number of secondary processors located in South Africa in the rooibos industry that produce green rooibos and extract, and many of them perform services that enable clients to obtain green rooibos and extract, in addition to the standard processing required for red rooibos. Beyond South Africa’s borders, a number of companies also provide extract production services.

Green rooibos is handled differently to red rooibos – and the one clear difference is that it does not undergo the enzymatic oxidation required for the better-known red form. Once harvested, the raw green rooibos is cut to size in a carving machine, blanched and is then typically machine-dried in a processing facility.

Rooibos extract is processed differently to rooibos tea, as the desired consistency is in powder or liquid form. Extract is made from whole rooibos material (including by-product). Larger sticks can be hammer-milled to refine the material further prior to extract production.

Extract is the form which is increasingly sought out by the food, beverage and cosmetics industries, as it is an ideal ingredient that provides both flavour and health benefits. In the cosmetics industry, the health-giving properties of rooibos have made extract an area of significant interest, with the extract blended into a growing number of creams, moisturisers and topical applications. As understood by the writer of this article, the powder form is used for food, beverages and cosmetics, due its suitability for formulation.

Powdered extract is particularly ideal for the growing number of ready-to-drink and flavoured drinks that now include rooibos as an ingredient, and this application is being sought out for two reasons: on the one hand because rooibos has great colour and is an excellent base that blends well with fruit and berry flavours, and on the other as a result of being caffeine-free and having a number of health benefits.

Grading: In Pursuit of Colour and Taste

Though there is no clear standard on organoleptics, at the company level, expert graders generally evaluate the quality of rooibos and green rooibos according to a number of factors, including the colour of the dry and infused leaves, the intensity, colour and clarity of the infusion, as well as the flavour and taste.

High quality rooibos tea is characterised by herbal and floral notes and a distinctive sweet / caramel / honey scent; low-quality rooibos tea on the other hand would be bland, lacking in rich colour and displaying taste and aroma that is flat, or even features notes such as hay, grass or rubber.

The Rooibos Colour Wheel, shown below, is used by various companies in the industry to interpret rooibos organoleptically.

Phenolic content, specifically Aspalathin (which is unique to rooibos and plays a very big role in the current marketing success of rooibos as a healthy product), is closely linked to the quality of rooibos. Researchers Joubert and De Beer (2012) confirmed that quality grading is reflected in the phenolic composition and total antioxidant capacity of hot water fermented rooibos extracts, prepared according to simulated industrial conditions which is to steep five gram of rooibos tea in hot water for 3-5 minutes. The large, natural variations in values for total polyphenol content and total antioxidant capacity in rooibos were confirmed by another study by Joubert et al (2012).

Another step forward in defining rooibos quality was the aroma profiles and aroma wheel developed in 2016. In recent years concerted efforts to improve the quality of the product and to develop quality control tools for use in the rooibos tea industry have been crucial elements in elevating the product to an international standard, although consensus on a minimum quality standard for rooibos is still emerging.

The Regulation and Safety of Rooibos Processing

South African standards regarding the safety and hygiene of agricultural food products of plant origin destined for export are governed by the Agricultural Product Standards Act (Act No.119 of 1990, SA Government Gazette).

In line with this legislation and in conformance with SAGAP (South African Good Agricultural Practices) requirements, producers must have a management system in place to keep record of field names and locations, spray records, harvest dates and harvest loads, so that they are able to pinpoint the field that each rooibos lot originates from. This is essential for the purpose of traceability and transparency – an element increasingly being sought by discerning consumers the world over, especially in light of the focus on health & well-being, as well as the interest in the origin, and organic and ethical practices, related to consumer products.

All processors practice HACCP systems and controls which ensure that good manufacturing practices are implemented, and risk assessments are done at critical control points, and consequently risks are reduced and eliminated.

Monitoring systems must be in place to manage food safety risks identified. Rooibos deliveries to processors are managed according to the raw material receiving procedure under the processor’s specific good manufacturing practice (GMP) for raw materials. When delivered from a primary processor, a representative sample is taken from the raw material load, graded and retained as per the procedure of the processor.

Though deregulated, rooibos producers in the industry do adhere to a range of standards which determine the quality of the variety of products that are brought to market. Among these, the Agricultural Product Standards Act defines the standards regarding the quality and the requirements regarding the packing, marking and labelling of rooibos and rooibos mixtures.

When packaged for shipping, bulk rooibos is typically packaged in 4-layer brown paper bags (which have an inner layer to prevent ingress of moisture and keep the contents as stable as possible in transit) and then packed onto a pallet as container loads of 9 tons in 20-foot containers, or 18 tons in 40-foot containers, in the manner shown below.

When it comes to the usage of names and words in relation to the branding and marketing of rooibos products, there have been some positive movements in recent years to prevent the misuse of the name ‘rooibos’. These include legal engagements with companies in the USA and France who attempted to copyright the word, and both of whom failed in their efforts, thanks to a combined response from the rooibos industry and South African government. As it stands today, products that do not originate from South Africa and do not contain a minimum amount of rooibos tea cannot make use of the word ‘rooibos’, or create the impression that the contents are rooibos.

Adding to the protections against misuse, in late June 2021, rooibos was awarded Protected Designation of Origin status by the European Union, and from that time, certified rooibos products can proudly carry this designation wherever they are sold. This applies to any clients of ours, who will be able to similarly display this badge of authenticity on their products. This is a move that not only enables tea brands to charge a premium for their products, but also makes it possible for consumers to be sure that the rooibos product they buy is certified as coming only from our rooibos producing region.

Here at Klipopmekaar, we observe all regulations and standards to the fullest. In some areas, we in fact go well beyond the required standards, in order to be able to answer our clients’ interests as far as the purity, consistency and quality of our rooibos products.

We hope you’ve enjoyed learning about the processing of rooibos from us – if you’re interested in other aspects of rooibos such as botany and the fascinating history of the rooibos tea, we can recommend reading our other articles ‘The Botany of Rooibos’ and ‘The History of Rooibos Tea’ here on our website.